IPX3 AND IPX4 SPRAY NOZZLES

IPX5 AND IPX6 JET NOZZLES

Applications:

Premier's IPX3, IPX4, IPX5 and IPX6 portable spray nozzles/ sprays are designed to perform water protection tests in all kinds of products.

It is a better and cost effective option when water protection tests are necessary.

These spray testers are an alternative to the oscillating tube for establishing the degree of protection against ingress water.

Download PDF

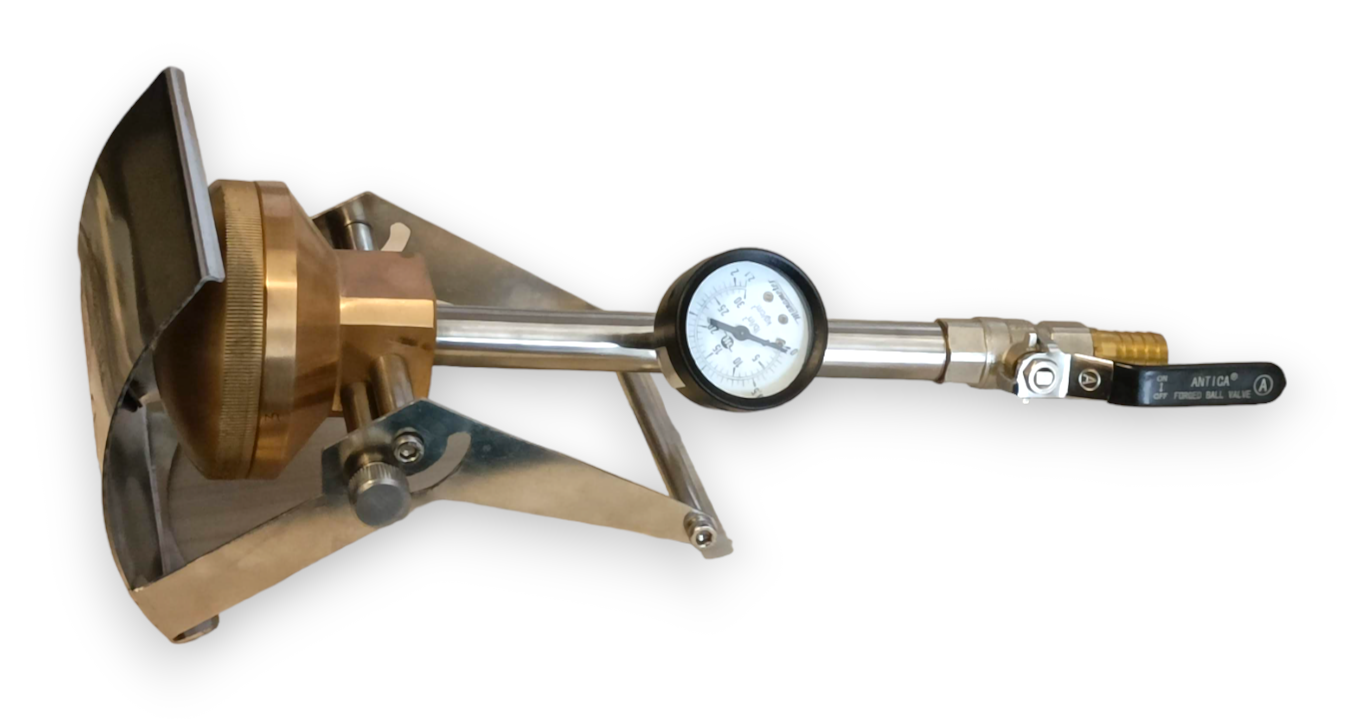

IP X3 & X4 SPRAY NOZZLE

MODEL : PE IPX34

Premier's IP X3/ 4 Spray nozzle is a hand-held test device to verify protection against spraying and splashing water.

The water pressure can be adjusted using the flow control knob on the device to give the required flow rate.

The pressure can be seen on the gauge which is convenient positioned by the Spray Tester IP x 3/4.

The spray pattern of the nozzle is made to the specifications of IEC 60529.

The removable shield feature makes it easy to test without the interference of the shield.

SPECIFICATIONS :

Construction : Brass and Stainless Steel

Thread Size : 1/2" BPST

Pressure Gauge : 0- 4 bar dial gauge.

No of holes: 121

Orifice Diameter : 0.5 mm

Water supply : Water flow rate is 50~150kpa clean water.

SPRAY NOZZLE PARAMETERS:

External diameter: 102 mm

Spherical diameter: S75.5mm

There is a middle hole and there are 24 holes in the internal circle of holes of which the included angle is 30 °.

There are 96 holes in the external circle of holes of which the included angle is 15 °.

Water flow: 10L/min &plusm; 5%, Flow is adjustable

Range of pressure gauge : 0-4 bar

Baffle: Removable- as per standard requirements

Site requirements: Dedicated IP waterproof test room. The ground should be flat with illumination with good function of inflow and drainage.

Standard Reference: IEC60529, IEC60598-1, IEC 60335-1, IEC60745-1

Check our video on IPX3/4 spray nozzle complete setup:

If you are unable to see the video, Click Here

IP X5 & X6 JET NOZZLE

MODEL : PE IPX56

The test is made by spraying the enclosure from all practicable directions with a jet of water from the Premiers IP X5/6 test nozzle as shown in figure 6 of IEC 60529.

This device is used for the verification test of the degree of protection to the risks of water penetration provided by wrapper of equipment in compliance with the second digit No. 5 (IPX5) and the second digit No. 6 (IPX6) according to IEC 60529.

The device is a specific Water Jet Hose Nozzle to throw a jet of water. Their use is described in paragraph 14.2.5 of IEC 60529 (IPX5) and in paragraph 14.2.6 of IEC 60529

SPECIFICATIONS :

Construction : Brass and Stainless Steel

Nozzle Diameter IPX5: Φ 6.3 mm.

Nozzle Diameter IPX6: Φ 12.5 mm.

Water Flow IPX5: 12.5 ± 0.625 L/min

Water Flow IPX6: 100 ± 0.625L/min.

Testing time: Not less than 1 min/m2 or 3 mins, whichever is higher

The distance from jet nozzle to enclosure: 2.5-3m

Pressure Gauge: 0 - 2.5 bar dial gauge

Site requirements: Dedicated IP waterproof test room. The ground should be flat with illumination with good function of inflow and drainage.

Reference standards: IEC60529,IEC60598-1,IEC60335-1,IEC60745-1

Download PDF

Other Relevant Products:

Tensile Tester- Click here

Flexing Tester- Click here

Composite Test Panel-Click here

Temperature Indicator-Click here